The air-cooled chiller

Description

Windmatik is a monobloc air-cooled chiller using ammonia as the refrigerant fluid, designed for efficiency and sustainability. Thanks to its optimised configuration, Windmatik offers high cooling capacity in a small space, perfectly meeting the needs of industry and civil and non-industrial air-conditioning. The EC fans, together with the soundproof casing for the semi-hermetic compressor, ensure extremely low noise levels, guaranteeing maximum operational silence.

To maximise heat exchange while maintaining compact dimensions, Windmatik is equipped with high-efficiency V-Shape condensing coils. This configuration allows a larger exchange surface area in a smaller footprint, improving heat dissipation even in critical environmental conditions and contributing to the high overall efficiency of the system.

Features

General characteristics

- Temperature range: +15°C to -20°C

- Cooling capacity: up to 1100 kW

- Low refrigerant charge

- Easy and simple transport and installation

- V-Shape condensing coils give greater heat exchange with less floor space requirementsa

- Condensation pressure control via EC fans

- State-of-the-art aluminium microchannel technology

- Very high heat exchange coefficient

- Higher yield per occupied square metre in plan

- PED 97/23/EC certification and tested according to ISO 9001:2008

Options and accessories

- Motors and inverters available with IE4 efficiency

- Cooling and electrical energy metering system with “certified” COP

- Partial heat recovery

- Available with on-board pumping units

- Anti-corrosion treatment for condensing coils

- Super-silenced versions

Strenghts

Environmentally friendly

Environmentally friendly

Ammonia, environmentally friendly, natural, guarantees maximum plant efficiency. Ammonia is the only natural refrigerant with GWP=0 and ODP=0.

Sustainable

Sustainable

Windmatik, due to its characteristics and the use of ammonia as a refrigerant, can be defined as a sustainable chiller. Its efficiency makes it possible to reduce energy requirements and thus CO2 emissions.

Resistant

Resistant

Thanks to an advanced design and highly resistant materials, this chiller maintains its operational efficiency even at outside temperatures of up to 45°C, without compromising cooling quality.

Efficient

Efficient

The efficiency of the ammonia used as a refrigerant results in annual savings of 30% compared to conventional chillers using F-GAS or HFO. In addition, aluminium microchannel condenser coils ensure even greater efficiency.

Quiet

Quiet

The use of low-noise EC fans ensures efficient airflow without generating vibrations and disturbing sounds, making Windmatik an ideal solution for environments where acoustic comfort is paramount.

Compact

Compact

Thanks to intelligent optimisation of the internal space and components, such as the condenser coils, this chiller occupies less square metres than other cooling systems, without compromising operating efficiency.

Tested

Tested

Each Windmatik unit is tested at the factory to ensure that it is fully functional for the customer. Testing can be carried out in-person with the customer or remotely to optimise cost and time for the customer.

24 /7 Monitoring

24 /7 Monitoring

Thanks to our Telematik system, we are able to monitor the machine remotely to analyse its correct operation and intervene promptly.

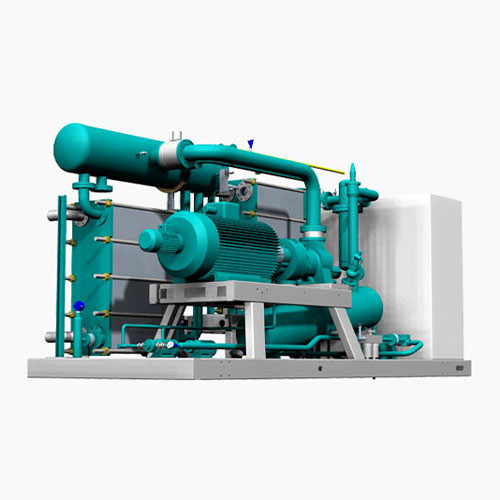

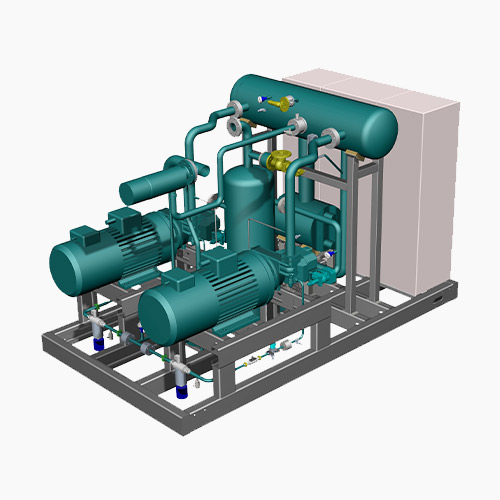

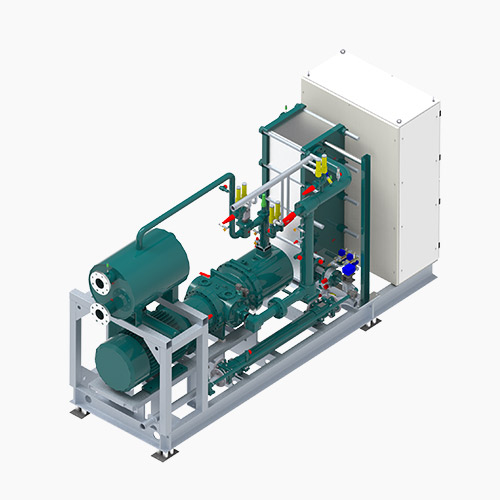

Zeromatik

Zeromatik is Zudek's accessory that allows any of our chillers to produce cold water consistently. The system optimally utilizes plate heat exchangers, where water is cooled to a temperature close to freezing. This is possible thanks to precise and controlled management of ammonia evaporation.

The Zeromatik system for cold water production can be installed in all Zudek solutions, including water-cooled systems, air-cooled systems, and water and ammonia absorption chillers.

Many dairy industry companies, where cold water is a critical element in the production process, have already installed this system.

But they are not the only ones! In fact, Zeromatik is the best solution for effectively managing various types of processes, such as vegetable cooling, carbonated beverage bottling, and activities in wineries.

Strengths

Efficient

Efficient

Zeromatik allows you to replace the ice storage tanks typically used for cold water production. This results in significant energy and operational cost savings.

Compact

Compact

Zeromatik is small in size, making it easy to integrate into existing systems

Versatile

Versatile

Zeromatik is available for both water-cooled and air-cooled compression chillers, as well as absorption chillers. Moreover, it can be easily integrated into existing ammonia refrigeration systems.

Consistent

Consistent

Zeromatik enables the production of chilled water at a constant temperature without interruptions. This system allows for continuous operation at the same temperature 24 hours a day.

Reliable

Reliable

Custom-sized for the customer and thanks to Zudek's control logic, there is no risk of freezing.