In 2024, Zudek upgraded AD Harvey Poultry’s processing plant with a high-efficiency ammonia-based cooling and heating system. The solution replaced diesel boilers and synthetic refrigerants, cutting CO₂ emissions by 59%, lowering energy costs, and increasing capacity to 7,200 chickens/hour. A benchmark in sustainable poultry processing and industrial refrigeration.

In 2024, Zudek had the privilege of designing and implementing an advanced cooling and heating system for UK’s poultry producers, AD Harvey Poultry. This project aimed to replace traditional synthetic refrigerant-based systems with natural ammonia-based solutions and decarbonize the heating production by replacing a diesel fired boiler with an electrified heat pump, significantly improving both energy efficiency and environmental sustainability.

The poultry industry in the UK is a key sector, with a strong focus on chicken and turkey production. As one of Europe’s largest poultry-producing nations, optimizing processing efficiency while reducing environmental impact is crucial.

The Challenge

The client sought a solution to replace their existing system with a more sustainable, ammonia-based setup that could:

- Heat approximately 4,600 chickens per hour to +80°C

- Cool the same 4,600 chickens per hour from +40°C to +2°C

- Operate 10 hours a day, 5 days a week, for 52 weeks a year

- Scale up processing capacity from 4,600 to 7,200 chickens per hour

- Enhance product quality and consistency

- Achieve carbon neutrality by eliminating diesel boilers and synthetic refrigerants

Our Solution

To meet these ambitious goals, Zudek deployed:

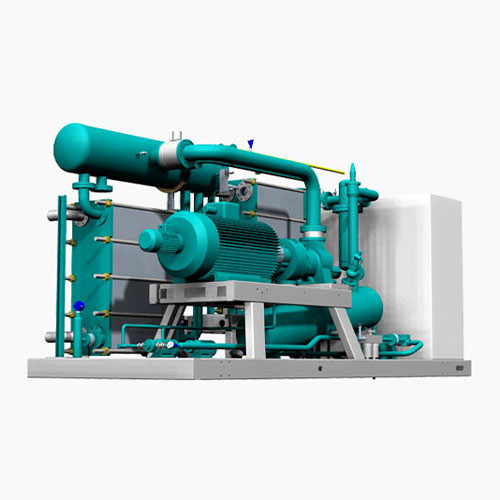

- Ecomatik – a 740-kW water-cooled chiller at -12°C using ammonia as a refrigerant

- Recumatik – a 600-kW high-temperature heat pump at 80°C, also ammonia-based

The Results

The new integrated system delivered tangible benefits:

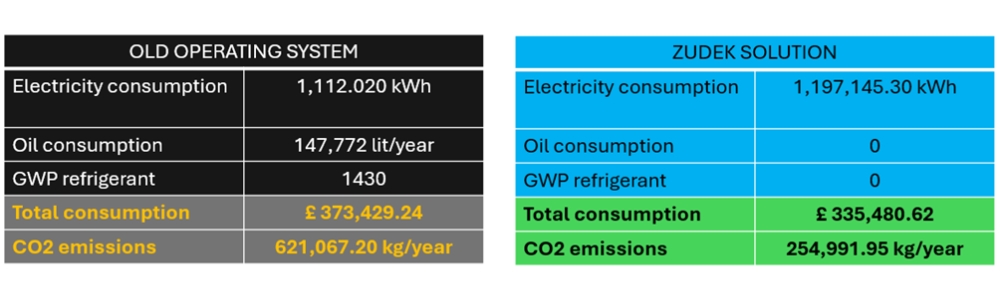

- Integrated heating and cooling, replacing separate systems

- Enhanced efficiency, cutting CO₂ emissions from 621,067.20 kg/year to 254,991.95 kg/year

- Cost savings, reducing operational expenses from £373,429.24 to £335,480.62

This project exemplifies Zudek’s commitment to sustainable industrial refrigeration, proving that natural refrigerants can drive both eco-friendly and cost-effective transformations in the food processing industry.

This project exemplifies Zudek’s commitment to sustainable industrial refrigeration, proving that natural refrigerants can drive both eco-friendly and cost-effective transformations in the food processing industry.