CO₂ from biogas and industrial processes can be purified and liquefied, turning emissions into a valuable resource. The Biomatik-CCS system shows how pollutants can be drastically reduced while obtaining food‑grade CO₂. A process that combines sustainability, efficiency, and new economic opportunities.

Purification and Liquefaction of CO₂: Turning Emissions into a Resource

Today’s climate challenge requires us to rethink the role of CO₂. For a long time, the carbon dioxide produced by biogas plants or industrial exhaust streams has been considered an unavoidable by‑product, destined either to disperse into the atmosphere or to be stored underground. Today, however, technology allows us to look at this gas from a different perspective: no longer as a problem, but as a resource that can be recovered and enhanced.

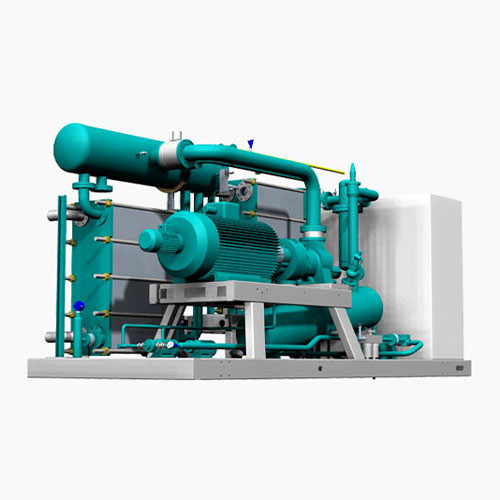

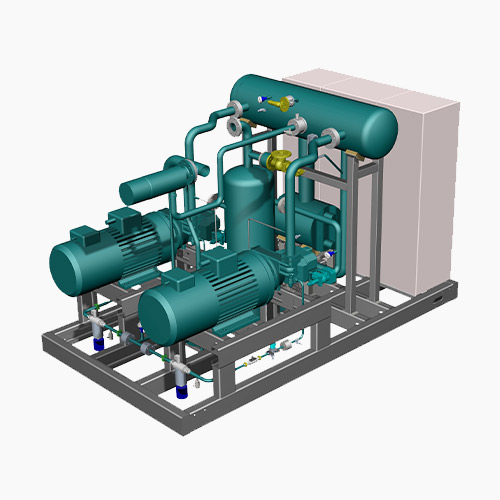

In biogas plants, organic biomass generates a mixture composed mainly of methane and CO₂. While methane is concentrated and upgraded into biomethane, CO₂ can be captured and subjected to purification processes that remove impurities and unwanted compounds. Once liquefied, this “BioCO₂” can reach, through specific treatments, high quality standards up to food‑grade level, making it suitable for numerous applications: from the food and beverage industry to dry ice production, as well as agricultural and pharmaceutical uses.

The same principle applies to exhaust gases from industrial processes. Through dedicated capture systems, CO₂ is separated from other gases, purified, and liquefied. In this way, emissions are reduced and a circular economy model is promoted, where what was once waste is reintroduced into production cycles.

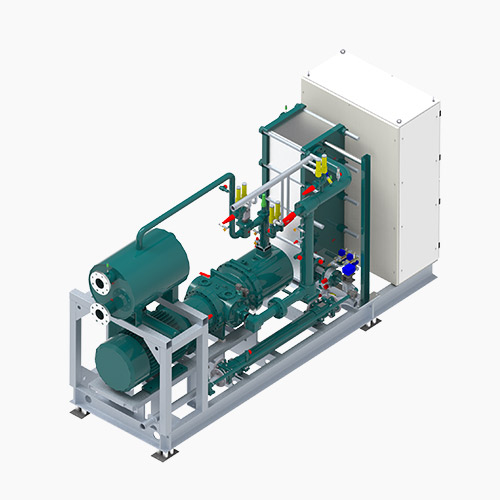

Concrete Results: Biomatik‑CCS

The effectiveness of this approach is demonstrated by the installation of the Biomatik‑CCS system at an industrial facility in Portugal. Before the installation of our system, the exhaust gases contained 15.6% CO₂ and high levels of impurities such as SO₂ (23.1 ppm), COS (35.5 ppm) and HCN (5 ppm), values exceeding the limits set by international standards (EIGA/ISBT).

After the implementation of Biomatik‑CCS, the results were clear and measurable. CO₂ concentration in the exhaust dropped to 0.8%, while harmful compounds were drastically reduced: SO₂ to 0.1 ppm, COS to 0.37 ppm and HCN to 3 ppm. The physical characteristics of the emissions also changed significantly: stack temperature decreased from over 440°C to just 40°C, and volumetric flow was reduced from 17,444 m³/h to 7,300 m³/h.

These results demonstrate not only a drastic reduction in pollutants released into the atmosphere, but also the possibility of recovering CO₂ in a form that meets the strictest food‑grade requirements. In other words, what was once an environmental burden can now be transformed into a valuable product.

The value of this process is not only environmental. Liquid CO₂ is a marketable product, demanded by various industries and capable of generating new economic opportunities. It is proof that sustainability and efficiency can coexist, turning emission reduction into a competitive advantage.